The invention of he wheel is considered to be one of the most significant milestones in Human history. Wheels are useful not just as a mode of transport, but in a wide range of manufacturing processes, including spinning yarns, lathing wood, and the manufacture of ceramics. The origin of these technologies is obscure, and they were probably arrived at independently by several different civilisations. The possibility that potter's wheels were used by the ancient Indus Civilisation of northwestern India (which lasted roughly from 2500 BC to 1900 BC) was first suggested by Ernest Mackay in 1938, and has been debated by archaeologists ever since. Opinions in the field fall into two main camps, with the first arguing that spinning wheels appeared very early in the history of this culture, and were a feature of the ceramics it produced throughout its history, while the other argues that the use of wheels in the manufacture of ceramics was rare and very limited, probably restricted to the finishing stages of pottery items made by other methods.

In a paper published in the Journal of Anthropological Archaeology on 26 October 2021, Alessandro Ceccarelli of the Department of Archaeology and McDonald Institute for Archaeological Research at the University of Cambridge, Patrick Quinn of the Institute of Archaeology at University College London, Ravindra Singh of the Department of Ancient Indian History, Culture, and Archaeology at Banaras Hindu University, and Cameron Petrie, also of the Department of Archaeology and McDonald Institute for Archaeological Research at the University of Cambridge, present the results of a study which examined pottery fragments from Indus Civilisation archaeological sites in Haryana State, northwest India, in order to try to understand the techniques used in their manufacture.

In order to assess pottery methods used by the Indus Civilisation, Ceccarelli et al. first examined the tools and techniques used by these ancient potters. Unfortunately, almost no tools associated with the manufacture of pottery have been found at Indus Civilisation sites, meaning that Ceccarelli et al. were obliged to make deductions about the types of tool used by the examination of traces on the pottery itself. This was made more complex by a variety of different terms being used to describe similar processes in different publications, although by concentrating only on wheel-driven pottery Ceccarelli et al. were able to avoid much of this confusion, focussing on the differences between wheel finished pottery.

A variety of different wheels, including slow wheels, fast wheels, kick-wheels, tournettes, and turntables (there is some degree of overlap between these terms) can be used in finishing, enabling the potter to rotate the item so that it can be worked from any angle, without the need to pick it up. In wheel throwing, soft clay is placed upon a wheel and spun rapidly, enabling the potter to use rotational kinematic energy to help form the material into the desired item. This can, again, be achieved using a variety of different wheels, so that the important factor for the archaeologist trying to decipher this technology is not the nature of the tools used, but rather the way in which they were used.

A number of different lines of evidence have been taken as indicators of wheel throwing by Indus Civilisation potters, including parallel striations on finished pottery, concentric markings on the base of pottery items, and high levels of symmetry, which are hard to achieve by other techniques. These features are present on many small and medium sized pottery items from Indus Civilisation sites, particularly Mohenjo-Daro, Harappa, and Nausharo, and have been used to suggest the use of footdriven double or Persian wheels. However, no such wheels have ever been found at any Indus Civilisation site, and not every site associated with the culture has produced pottery with these traces.

More recent studies of pottery at third millennium BC archaeological sites across the area that includes Iran and northwest India have revealed the use of a wide range of pottery techniques. Many of these, such as those from Godin Tepe and Shahr-i Sokhta in Iran, and Kalibangan in Rajasthan, appear to have used wheels for finishing, but not throwing, pottery, with the initial formation of ceramics being done largely by coiling.

Traditionally, archaeologists have tended to see the development of pottery making techniques as a linear process, with methods seen as more advanced and efficient steadily replacing older, less efficient, methods. However, studies of ceramic making in Bronze Age Greece have revealed a more complex pattern, with technologies seen by modern archaeologists as 'primitive' and 'advanced' frequently being used alongside one-another. This discovery of different pottery making methods being used in close proximity to one-another has been interpreted as having profound social significance, with implications about the ways in which information was passes between different groups in Ancient Greece.

Nevertheless, the throwing of pottery on fast wheels is still generally considered to have revolutionised pot-making across the Agean and Levantine regions, enabling the rapid production of much more standardised pottery than was previously possible. Thus, it is still assumed that communities began with hand-made clay objects, then adopted wheels for the finishing process, before finally switching to throwing pots on wheels, even if the speed at which different communities adopted these techniques varied.

When examining Indus Civilisation material, Ceccareli et al. considered two possibilities; material showing signs of different manufacturing techniques might be the result of different communities of craftsmen living in the same area using different techniques to make similar objects, or it might be the result of craftsmen using different techniques to make different items (bottles, jars, dishes, bowls, etc.).

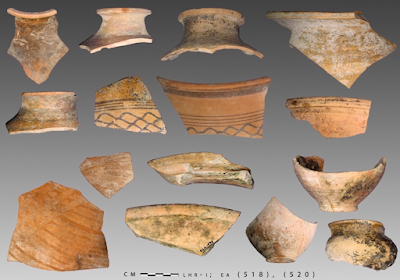

To this end, material from two sites was examined, both in Haryana State, India; Lohari Ragho I, which was occupied during the pre-urban and urban periods, and Masdupur I, which was occupied during the urban and post-urban periods. A total of 27 502 pottery fragments were recovered from Lohari Ragho I, and 16 752 from Masdupur I. About 88% of the material from Lohari Ragho I was made from fine-paste ceramic material, and about 52% of that from Masdupur I, while about 44% of the material from Masdupur I appeared to represent course ceramic material, such as building materials, organic-rich-paste vessels, and terracotta cakes.

Multiple ceramic fabrics were found at both localities, although Ceccareli et al. concentrated on the fine-paste material, due to the friable nature of the course material. These were sorted into material showing signs of rotational shaping during manufacture, and material that showed signs of other manufacturing techniques.

A lot of the material, from both sites, showed signs of initial forming by coiling, with 38% of the material from Lohari Ragho I, and 32% of the material from Masdupur I showing signs of multiple techniques being used during formation.

One of the most common techniques, at both Lohari Ragho I and Masdupur I, was the forming of the basic shape of the pottery by coiling, followed by the smoothing of the surface by some form of scraping. This method has previously been observed at the Indus Civilisation sites of Farmana, Masudpur I and Masudpur VII. Some of this material showed signs of being smoothed on a rotational device, which results in the presence of parallel striations, whereas other material showed no evidence of this.

At Lohari Ragho I, 10 368 pottery fragments (38% of the total 27 502 fragments recovered) showed signs of having been initially formed by coiling, with 7881 fragments (28% of the total), showing signs of smoothing by scraping, and 9404 fragments (34% of the total), showing signs of having been rotated during their manufacture.

At Masdupur I 8639 fragments (52% of the total) showed signs of coiling, with 5901 fragments (30% of the total) showing signs of smoothing by scraping without rotation. A selection of 846 fragments were chosen for a more detailed analysis, of which 693 were fine-paste ceramics from which evidence of the finishing method could be determined; of these 305 showed signs of the use of rotational motion, while 382 were clearly made and finished without any rotation being employed.

Based upon this, the fragments were divided into two groups. Group A comprised samples thought to have been made without the use of rotational devices. These fragments typically show numerous striations, but these are not parallel, it is also often possible to see signs of the original coiling on the surface, particularly on the inner surface of the pot.

The second group, Group B, showed abundant parallel scape-marks, consistent with the use of a rotational device being used in their manufacture. These are present on fragments from all parts of pottery vessels; however, while the fragments from the upper parts of vessels are typically thin walled and show no signs of any other form of working, those from the lower part of vessels are usually thicker, and show signs of coiling and non-rotational scraping as well as rotational finishing, suggesting that the tops and bottoms of these vessels were made separately. Ceccareli et al. note that even where vessels show signs of rotational working across their entire surface, this cannot be taken as proof that no other technique were used during manufacture.

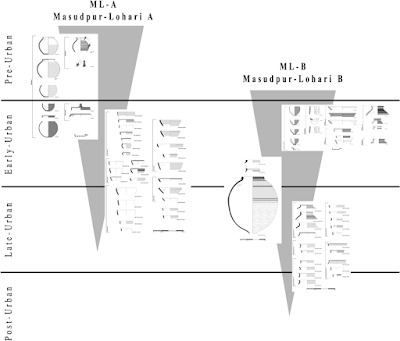

Working from these two groups, Ceccareli et al. suggest the presence of two separate ceramic traditions dominating the manufacture of ceramics at the two sites, which they name Indus Masudpur-Lohari A and Indus Masudpur-Lohari B.

The first of these traditions, Indus Masudpur-Lohari A, comprises vessels with a red colouration, made from a clay paste rich in limestone fragments, with little or no evidence of rotational working being used in manufacture. The quality of these vessels is variable, but does include high-quality items, although the walls and rims of the vessels are often irregular, showing variability in the manufacturing process. The outer side of the vessels tend to be smoother, and either red in colour or painted, the inner surfaces are less well finished. Where the pottery is broken, the interior of the clay is red throughout, suggesting complete oxidation has been accomplished during firing. The objects made in this way are mostly bowls, jars, and jugs. Decoration on the outside of these vessels typically includes incised grooves and black lines of paint. Pottery items similar to these have also been reported from Sothi, Siswal, and Kalibanghan.

The second tradition, Masudpur-Lohari B, comprises vessels that appear to have been originally formed by coiling, then finished on a wheel. These vessels show parallel striations typical of wheel-working across their entire surfaces, although it does appear that their upper parts were made separately to their lower parts. The clay from which these vessels was made shows only small inclusions. These vessels were typically decorated with a red slip (layer of liquified clay applied over the outer surface of a pottery item), as well as black paint markings. Vessels made in this tradition include dishes, bowls, jars, and goblets. Similar items have been found at Rakhigarhi, Girawad, Masudpur I/VII, and Mitathal, as well as some items from Farmana.

The presence of two different ceramic-making traditions both present across a wide area of northwestern India in the third millennium BC has implications for our understanding of the culture of this civilisation, and the way in which new innovations, such as the potter's wheel, spread through this culture. Only one of the two traditions present appears to have adopted the wheel as a way of finishing hand-made items, and neither shows evidence for throwing pots on wheel, in contrast with earlier interpretations of pottery making in the Indus Civilisation.

The two different traditions suggest the presence of two different pottery-making communities being present over a wide geographical area for a time period of several centuries, although Indus Masudpur-Lohari A does appear to originate before Indus Masudpur-Lohari B, and disapear slightly earlier. Furthermore, the two technologies are similar enough that they do appear to have a common origin. The presence of two similar, but distinct, cultural traditions over such a long period of time implies two groups that were making a conscious effort to maintain their cultural identities, even though these cultures appear to have had a common origin.

The presence of multiple ceramics-making traditions has previously been noted at other sites in Harappa and Gujarat, as well as other sites across northwestern India and Pakistan, but this is the first time that their continued co-existence for such a long period has been documented, something Ceccareli et al. suggest might be linked to different social units with their own rolls within society consciously maintaining their separate technical traditions for a long period of time.

See also...

Follow Sciency Thoughts on Facebook.

Follow Sciency Thoughts on Twitter.