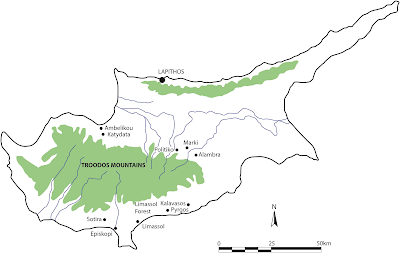

The Middle Bronze Age in Cyprus (roughly 2000–1700 BC) has often been seen as comprised of agropastoral communities largely isolated from the wider eastern Mediterranean world. Current excavations and new readings of ‘legacy’ data, however, are challenging such views, suggesting that Middle Bronze Age communities were significantly more complex and interconnected and that the internationalism of Late Bronze Age Cyprus, largely based on the trade of Cypriot copper, had its antecedents in the Middle Bronze Age. The site of Lapithos, located on the north coast of Cyprus, is of major importance in this discussion. Some 140 tombs excavated here in the early 20th century produced over 1800 copper-base artefacts and more than 150 imported objects, primarily of faience, gold, silver, lead, copper and bronze. These suggest that the settlement was involved in an internal procurement network, which linked Lapithos with mining villages located close to copper ore bodies in the foothills of the Troodos Mountains, and an international maritime trade in metals and other goods conducted along sea routes which passed between the south coast of Anatolia and the north coast of Cyprus in the first half of the 2nd Millennium BC.

In a paper published in the Journal of Archaeological Science on 18 November 2020, Andreas Charalambous of the Archaeological Research Unit at the University of Cyprus, and Jennifer Webb, also of the Archaeological Research Unit at the University of Cyprus, and of the Department of Archaeology and History at La Trobe University, discuss the metal content of bronze artifacts from the Lapithos area, and the implications of this for trade with other areas around the eastern Mediterranean.

Four hundred and fifteen copper-base objects from Lapithos were analysed for this study, using portable X-Ray Fluorescence Spectrometry. They constitute one of the largest site-specific datasets for the Bronze Age Eastern Mediterranean and offer an opportunity to investigate the use of non-local tin and alloying, recycling and mixing practices on Cyprus in the Middle Bronze Age, and the extent to which Lapithos may have been involved in an international trade in raw metals. The analyses also provide an opportunity, within the precision limits imposed by the use of X-Ray Fluorescence Spectrometry, to investigate changes in alloy composition over time and consider the degree to which alloy types may have been preferred for certain artefact categories.

The objects are held by the Cyprus Museum in Nicosia. They form part of an assemblage of over 1125 metal artefacts recovered from 80 tombs excavated in 1913 and 1917, the remainder of which can no longer be securely identified. The associated settlement remains unknown and this part of the island has been inaccessible for excavation by archaeologists from outside since the Turkish invasion of Cyprus in 1974.

The artefacts belong to four broad categories—weapons (spearheads) and tool/weapons (daggers, axes), tools (needles, awls, chisels), items used for personal grooming (razors, tweezers), including clothing or shroud fasteners (pins, toggle pins), and ornaments (spiral rings), and those of uncertain purpose (‘hooks’, small spatula?). In addition, a number of items occur only once in the assemblage. The relative incidence of sampled objects broadly reflects their relative incidence in the overall assemblage. Several types, most notably the spiral rings, are, however, significantly underrepresented

and others (beads and bracelets), which are relatively rare overall, do not appear among the analysed objects.

and others (beads and bracelets), which are relatively rare overall, do not appear among the analysed objects.

Artefact types in the analysed assemblage. (a) Spearheads, (b) Daggers (knives), (c) axes, (d) awls, (e) chisel, (f) needles, (g) razors, (h) tweezers, (i) spiral, (j) spatula (?), (k) hook, (l) pins, (m) toggle pins. Charalambous & Webb (2019).

The depositional contexts of the artefacts are dated by the associated pottery. Fine-scale chronological attributions, however, are made difficult by the long-term use of tomb chambers and disturbance caused by subsequent burials, flooding and roof-fall. For this reason, dates of deposition are assigned to two broad phases identified as early/middle Middle Bronze Age (roughly 2000-1800 BC) and middle/late Middle Bronze Age (roughly 1850-1690 BC), which may be reliably dated by the associated ceramics. While the earliest artefacts may belong to the last phase of the Early Bronze Age (roughly 2100–1950 BC), the majority were deposited during the Middle Bronze Age, with a marked increase in the rate of deposition over this period and changes in the form and incidence of some artefact types.

The results of the X-Ray Fluorescence Spectrometry analysis may be compared with those obtained by Neutron Activation Analysis for another 75 copper-base artefacts recovered at Lapithos in 1927. Elemental data for 38 of these, along with the results of Lead Isotope Analysis, were published in 1994, and the full set is available in the Oxford Archaeological Lead Isotope Database. These objects include 12 spearheads, 13 daggers and a rivet, 8 axes, 4 awls, 1 chisel, 1 needle, 6 razors, 7 tweezers, 11 pins, 7 toggle pins, 2 spirals, a ‘button’ or spiral and a bracelet or earring. In addition, 30 metal objects from tombs excavated at Lapithos in 1931 were subject to Proton-induced X-ray Emission Analysis in the late 1980s. They include 13 spearheads, 8 daggers, an axe, an awl, 3 razors and 4 toggle pins. Together, the three sets of results provide compositional data for 520 artefacts of all major artefact groups from Lapithos.

Handheld X-Ray Fluorescence Spectrometry devices have been used successfully to derive compositional data from archaeological materials of various types in numerous recent case studies. This method examines only the surface of an object, where some alloying metals and impurities may be more or less abundant than others. It thus involves increased sampling uncertainty compared to more invasive techniques, but similar analyses have proved successful in identifying the major alloyed elements in prehistoric artefacts, while tending to overestimate the proportion of secondary metals. The latter is less of an issue for qualitative analyses where the focus is on the identification of alloys and their distribution among object classes and over time. For such purposes, results obtained by the use of non-invasive handheld X-Ray Fluorescence Spectrometry devices have been demonstrated to be as useful as those generated by invasive analytical approaches.

The data acquired by X-Ray Fluorescence Spectrometry on weight percent concentrations of secondary metals (Tin, Arsenic, Lead, Zn), however, should be treated with caution in what follows, as quantities may be under or, more likely, overestimated as a result of corrosion or patination. While all analysed objects had been cleaned in the Cyprus Museum, removing much of the surface encrustation, the metal at and beneath the original surface is still affected by corrosion to variable depths, given that the copper of the surface encrustations must have been leached out, mobilised and re-deposited from this near-surface original metal. This process of copper depletion and the consequent enrichment of tin and lead at and below the original surface will inevitably have some affect on the data quality, at both the qualitative level of alloy identification and specific numerical values, particularly with regard to the reported concentrations of Tin and Lead, which may differ significantly from those of the bulk or core of the object.

Charalambous and Webb attempted to alleviate this problem, as far as possible, by adopting as a final value for each object the mean value of three to five measurements conducted on less visibly corroded areas. In some cases, where multiple such areas were detected, more than five measurements were taken. For each object, the elements detected in the multiple measurements were checked for consistency, setting as an acceptance criterion of about 10% relative deviation of the mean value for every element, and in cases of non-consistency the measurements were rejected.

In order to test potential problems arising from varying degrees of preservation and surface preparation, Pb and Sn values for 32 artefacts without visible surface corrosion and 32 with only small areas of relatively ‘clean’ surface, both randomly selected and of various artefact types, were compared. The results show no discrimination between the two groups, suggesting that, while corrosion may have affected ‘original surface’ readings, adding to the problem of data reliability in regard to the numerical values of Tin and Lead, the impact of this problem is unlikely to have differed significantly within the sample. Notably, also, the more corroded artefacts do not show higher concentrations of lead and tin.

Measurements were also taken on corroded and cleaner surface areas on the same artefact, in order to see how the level of corrosion had affected the composition, focusing on the secondary elements of Tin, Lead, Arsenic and Iron that were detected in the majority of the artefacts. Measurements on corrosion areas showed much lower values for Tin, Lead and Arsenic, when compared with those on original surfaces. Only Iron values were higher. If an object was free of visible corrosion, measurements were conducted across the surface in order to examine the homogeneity of the chemical composition.

Two objects in the X-Ray Fluorescence Spectrometry sample, a spearhead and axe, had also previously been subject to spectrographic analysis. The spearhead was identified in both the spectrographic and X-Ray Fluorescence Spectrometry analyses as Copper with an almost identical amount of Aresenic (0.7 and 0.6 wt% respectively). The axe was identified in both programs as a Copper-Aresenic-Tin alloy with similar readings of Aresenic (2.3 and 2.15 wt%) but a markedly higher spectrographic reading of Tin (about 9 wt%) compared to that achieved by X-Ray Fluorescence Spectrometry (3.5 wt%). This is perhaps to be explained by the likelihood that the drilled sample was taken before the object was cleaned and ‘may not have penetrated the corrosion very deeply’. The X-Ray Fluorescence Spectrometry result, achieved after removal of the surface encrustation, may be more accurate.

With regard to the identification of alloys, Charalambous and Webb used an elemental concentration of over 1.0 wt% for Aresenic and Tin. This reflects the level at which changes in mechanical properties are likely to have become evident to metalsmiths, but did not assume that these concentration limits define intentional alloys. In the case of Aresenic, in particular, the minimum presence required to distinguish the addition of this metal from the use of ores naturally rich in Arsenic is a matter of controversy and especially relevantb in the case of Cyprus, where polymetallic ores with a reported Arsenic content of 0.5–7.6 wt% are available in the Limassol Forest region. Previous works have suggested the presence of 1–2 wt.% Arsenic as indicative of an intentional alloy, however, other works propose 2.5 wt% as the minimum for deliberate Cypriot alloys. Charalambous and Webb's results do not suggest an obvious threshold, but a continuum in line with natural ore content and should probably be viewed as signalling the use of arsenic-rich ores rather than the addition of Aresenic for most Arsenical Copper objects.

Tin is rare in copper ore deposits generally and when present at more than 1.0% is usually assumed to have been added intentionally. Cypriot ores contain no Tin. This suggests that a 1 wt% threshold for the identification of Copper-Tin alloys is appropriate, whether as a result of recycling or mixing (using Cypriot Copper and imported Bronzes) or an intentional addition for the improvement of the metal.

The compositional analysis by X-Ray Fluorescence Spectrometry revealed significant variability, in terms of both alloying elements and alloy types, among the 415 Copper artefacts. Arsenical Bronze (Copper-Aresenic) is the most common (152 artefacts, 37%), while Arsenic-Tin Bronzes (Copper-Aresenic-Tin) occur at the second highest frequency (117 artefacts, 28%). Tin was recorded at over 1 wt% in 49% of the sample and Lead in 18%, while Zinc occurred at over 1 wt% in 6 artefacts. This higher than expected incidence of Copper-STin alloys and of Lead may be driven in part by our alloy threshold of 1 wt%, together with the likely enrichment of Tin and Lead at and beneath the original surface.

Tin occurs in detectable amounts in 283 artefacts (68% of the total), in concentrations ranging from 0.1 to 21.3 wt%. Notably, artefacts from the early/middle Middle Bronze Age have lower Tin concentrations overall than those in the middle/late Middle Bronze Age group, but there are high Tin Bronzes in the earlier period. The middle/late sample also shows a more even presence of Tin across the concentration range from 6 to 18 wt%.

Lead was detected in 90% of the assemblage (379 artefacts), in concentrations from 0.1 to 7.5 wt%. A single outlier is a razor with a Lead concentration of 15.5 wt%. The vast majority of artefacts (350) have a Lead concentration lower than 2 wt% (only 29 artefacts exceed 2 wt%). Iron was detected in all artefacts, in concentrations from 0.2 to 2.1 wt%, but the great majority have an iron content below 1 wt%. Sulphur was detected in 66% of the assemblage (278 artefacts), in concentrations from 0.3 to 2 wt% but, as with Iron, most artefacts have Sulphur concentrations below 1 wt%. Zinc was detected in 14 artefacts (0.5–4.5 wt%) and Antimony (Sb) in 14 artefacts (0.1–0.3 wt%).

Tin was not detected in 132 objects (32% of the total). One hundred and eighty-two contain traces to 6 wt.% Tin. Since Cypriot Copper ores do not contain Tin, the Tin concentration of the less than 6 wt% group is not due to impurities in the ore, and is best explained as a result of the melting down of scrap metal or Bronze artefacts mixed with Arsenical Copper. This is supported by the fact that the majority of low-Tin artefacts contain significant concentrations of Arsenic (over 1 wt%).

On the other hand, 101 objects have recorded concentrations of 6–21.3 wt% Tin. In this case, the great majority of artefacts contain much lower concentrations of Arsenic (Arsenic exceeds 1 wt% in only 17 artefacts), especially in the high-Tin group (over 13 wt%, 52 artefacts) where the Arsenic content is in almost all cases below 1 wt% (Arsenic exceeds 1 wt% in only 6 objects).

In comparing the results from the two phases, there is a decrease in the number of objects with no Tin, from 56% to 25% of the sample, with a corresponding increase in all other concentration groups. Notably, the increase in the traces to 6 wt.% group, from 30% to 48%, suggests a significant rise in the quantity of recycle metal, and specifically Tin Bronze, in circulation at Lapithos in the middle/late Middle Bronze Age; while the higher incidence of objects in the over 6 wt% groups (from 14% to 27%) indicates an increase also in the use of medium-to high-Tin Bronze.

A slight decrease overall in the presence of arsenic from the early/ middle to middle/late Middle Bronze Age has already been noted. A more nuanced decrease in the latter period of artefacts in the over 1 wt% Arsenic groups and a corresponding increase in the percentage in the low-Arsenic group (traces to 0.9 wt%). This drop-off in Aresenic content concomitant with an increase in the use of Tin may be due to a decrease over time in the use of high-Arsenic ores or increased recycling practices, as already suggested by the rise in the traces to 6 wt.% Tin group, with repeated melting and post-casting operations leading to a depletion of Arsenic by oxidation and evaporation of Arsenic Trioxide (As₂O₃) fumes.

The 41 spearheads are primarily of Copper-Arsenic, with a small number of unalloyed copper and Copper-Arsenic-Tin and one of Copper-Tin. Copper and Copper-Aresenic are also predominant among the 25 spearheads analysed by Proton-induced X-ray Emission Analysis and Neutron Activation Analysis. Tin is, however, present in the Proton-induced X-ray Emission Analysis and Neutron Activation Analysis samples at sub-alloy levels (less than 0.01–0.53 wt% and less than 0.01–0.93 wt% respectively), and in the X-Ray Fluorescence Spectrometry data from below detection levels to 19.3 wt%; with a median nondetectable value. Only two spearheads have a significant amount of Tin. The Aresenic readings in the X-Ray Fluorescence Spectrometry data are comparable, on median, with the Proton-induced X-ray Emission Analysis and Neutron Activation Analysis data and within the range of naturally occurring high Arsenic ores in most cases. Only seven spearheads with more than 4 wt% Aresenic might be considered deliberate Copper-Aresenic alloys. The low incidence of Tin Bronze is not surprising. If the effectiveness of a spearhead depended more on its momentum at impact than edge-sharpness, there may have been little mechanical benefit to be gained in using valuable Tin. Most previously analysed Cypriot spearheads are also of unalloyed Copper or Arsenical Copper.

The 85 daggers are primarily of Copper-Arsenic and Copper-Aresenic-Tin, with smaller numbers of Copper-Tin and unalloyed Copper. The incidence of Tin, particularly in the ternary alloy Copper-Aresenic-Tin, is significantly higher in the X-Ray Fluorescence Spectrometry sample than among 21 daggers analysed by Proton-induced X-ray Emission Analysis and Neutron Activation Analysis, with a consequent reduction in the incidence of Copper and Copper-Aresenic. Across all data sets, however, daggers show more compositional diversity than spearheads and a greater use of Tin. This suggests that Cypriot metalsmiths were aware of the advantages of using Tin Bronze, which can be hammered to produce a hard edge, for objects which required sharp and durable cutting edges.

The 31 axes are of Copper-Aresenic-Tin and Copper-Aresenic with one of unalloyed Copper. Tin is present below 1 wt% in 12 axes, with only 2 recording no Tin. The number with tin at over 1 wt% is high, at 53% of the sample, with a median of 1.3 wt%. Arsenic is present in all samples, with a median of 2.5 wt%. The Proton-induced X-ray Emission Analysis and Neutron Activation Analysis samples recorded a lower incidence of Tin alloys and a significantly lower median Tin content. While in both cases this may reflect the problem of surface Tin enrichment, the recorded presence of Tin at or over 1 wt% in over half the sample and at trace level in another 16 axes, together with lead at over 1 wt% in 5 examples, suggests that most are made of recycled Bronze or local Copper mixed with imported metal containing some Tin. It would seem that few, if any, of the Lapithos axes were made of Copper cast directly from Cypriot ores.

The 37 needles are of unalloyed copper and Copper-Aresenic-Tin, with lower numbers of Copper-Arsenic and Copper-Tin. The high incidence of unalloyed Copper for these simple items is not surprising. Traces of Tin (under 1 wt%) in only 5 of the 14 needles of unalloyed Copper and 2 of the 5 Copper-Arsenic needles also indicate more frequent use of first generation metal. Given, however, that there seems no reason to use Tin at all for such artefacts, the presence of more than 1 wt% Tin in 49% of the sample suggests that they were often made opportunistically from small quantities of metal prepared for other purposes or from recycled metal.

Half of the 16 awls are of Copper-Aresenic-Tin and the remainder of unalloyed Copper and Copper-Arsenic with one of Copper-Tin. While the sample is small, the prevalence of Tin, recorded at over 1 wt% in 56% of awls, is clear. The concentration of Tin ranges from less than 0.1 wt% to as high as 17.2 wt%, with a median of 1.65 wt%. Arsenic ranges from under 0.1–4.4 wt%, with a median of 1.35 wt%. Thus few awls appear to be deliberate Copper-Aresemnic alloys, while over half are Copper-Tin alloys. Another 2 have traces of Tin and appear, therefore, to be of recycled metal.

Ten of the 19 razors are Copper-Arsenic, with 5 of Copper-Tin, 3 of Copper-Arsenic-Tin and 1 of unalloyed Copper. The incidence of tin at recorded levels above 1 wt% in 42% of the sample is only slightly lower than that of daggers (44%). Surface readings on thin objects corroded from both sides can, however, appear richer in Tin than thicker objects of the same original composition which still have a less Tin-rich core preserved. Arsenic is present in the razor sample from below 0.1-4.3 wt%, with a median of 1.6 wt%. Nine razors analysed by Proton-induced X-ray Emission Analysis and Neutron Activation Analysis are also primarily of Copper-Aresenic, with 2 of unalloyed Copper and 1 of Copper-Aresnic-Tin. Earlier compositional data for razors show a similarly high incidence of unalloyed and Arsenical Copper (13 of 15 analysed razors).

Seventy percent (70%) of the 34 analysed tweezers are of Copper-Aresenic and Copper-Aresnic-Tin. Tin was recorded at over 1 wt% in 65% of these objects, with a median of 5.55 wt%, and 9 (26.5% of all tweezers and 40.9% of those with Tin) were recorded with tin levels above 10 wt% and up to 20.0 wt%. The median overall Tin content is 2.45 wt%. These high Tin readings may to some extent be due to problems noted above with respect to surface readings on razors. Tweezer blades are typically even thinner than razors. The incidence of Tin at above 1 wt% in the Neutron Activation Analysis data, however, is similar to that in the X-Ray Fluorescence Spectrometry sample, and 2 of the Copper-Tin examples also had high levels of Tin, at 11.4 wt% and 14.29 wt%.

The 48 plain pins (i.e. pins without eyelets) are compositionally diverse. The presence of Tin at over 1 wt% in only 26% of the sample is lower, and for the most part significantly lower, than in all other artefact groups except spearheads. The recorded Sn content ranges from under 0.1 wt% to 20.8 wt% with a median non-detected value. When present above 1 wt%, however, Tin concentrations have a median of 17 wt%. Plain pins are thus less likely than other artefact types (with the exception of spearheads) to contain Tin, but when they do they are all high-Tin bronzes. Arsenic levels range from under 0.1 wt% to 15.6 wt%, with a median of 1.4 wt%. The Copper-Zinc pin contains 4.2 wt% Zinc and is technically brass. It is of non-local form and almost certainly an import. Nine pins analysed by Neutron Activation Analysis show the same preference for Copper and Copper-Aresenic as the X-Ray Fluorescence Spectrometry sample. Arsenic levels range from 0.005 to 7.18 wt%, with a median of 2.34 wt%, higher than that of the X-Ray Fluorescence Spectrometry group.

The 77 toggle pins are also of varied composition, with only 4% of unalloyed Copper. Tin was recorded at over 1 wt% in 76% of the sample and Lead at over 1 wt% in 43%, in both cases at a much higher level than in other artefact categories. Toggle pins have the highest median incidence of Tin and the lowest median incidence of Arsenic in the assemblage, as well as a significant component of Lead, recorded from traces to as high as 7.5 wt%, with a median of 0.85 wt%. One toggle pin contains Zinc at 3.0 wt% and one of Copper-Aresenic showed traces of Silver (0.7 wt%). Ten toggle pins analysed by Proton-induced X-ray Emission Analysis and Neutron Activation Analysis are of Copper-Tin, with a single example of Copper-Arsenic. The median concentration of Tin, at 11.36 wt%, is higher than in the X-Ray Fluorescence Spectrometry sample. Arsenic levels were again lower than in other artefact categories, with a median of only 0.15 wt%.

Some of the high-Tin Bronze pins may be imports or local imitations of Levantine pins. Twenty-one examples with a domed head, 81% of which are of Copper-Tin with a median Tin content of 15.15 wt%, are of a type known in Syria and Lebanon from about 2000 BC onwards. Toggle pins with mushroom-shaped heads, on the other hand, are local products and also predominantly Copper-Tin (67.7% of 31 examples), with a lower but still significant median Tin content of 9.5 wt%.

Arsenical Copper has several technical advantages which are likely to have led either to the selection of Arsenic-rich, polymetallic ores from the Limassol Forest region of Cyprus, or the addition of imported Arsenic-rich minerals, such as realgar/orpiment, or possibly the artificial Iron-Arsenic alloy, Speiss, to copper obtained from other ore bodies on the island. While there is no direct evidence for exploitation of the Limassol Forest ore bodies during the prehistoric Bronze Age, or indeed of any ore body on the island with the exception of that at Ambelikou, Lead isotope data suggest the use of ore from Laxia tou Mavrou and Petromoutti in the Limassol area already in the Early Bronze Age. The consistent use of Copper-Arsenic during the Middle Bronze Age at Lapithos leaves no doubt that imported Arsenic Sulphide or, more likely, high-Arsenic Copper ores from the other side of the island were available in significant quantities.

Mechanical properties change significantly with Aresenic concentrations as low as 0.5 wt%. Copper with increased Arsenic content in solid solution can be more hardened by cold work and high-Arsenic alloys are frequently favoured for cutting, carving and sewing tools. The presence of Arsenic also lowers the melting point of Copper, acts as a deoxidant and improves castability, although alloys containing more than ca. 7–8 wt.% Arsenic rapidly become too brittle to work cold. The formation of an Arsenic-rich phase (Cu₃As) also gives a silvery colour to Arsenical Copper alloys with more than 4 wt% Arsenic.

The preference for Copper-Arsenic among analysed spearheads, at 59% of the assemblage, suggests that the advantages of Copper with over 1 wt% Arsenic for casting large objects which were required to be strong and durable and which would not significantly benefit from the addition of Tin were understood by metalsmiths. The maximum recorded concentration of Aresenic, at 6.5 wt%, further suggests an awareness of the brittleness associated with alloys containing more than 7–8 wt.% Arsenic, while the occurrence of Aresenuc at over 4 wt% in 6 spearheads may indicate an intention in some instances to achieve a silvery surface colour.

The other artefact class in which Copper-Aresenic predominates, at 50% of the assemblage, is razors. It may be that metalsmiths understood that the greater ductility and toughness of Copper-Arsenic over unalloyed copper and Copper-Tin alloys made it better suited to the production of thinly hammered objects. The maximum recorded level of Arsenic, at 4.3 wt%, is again well below the brittleness threshold.

Copper-Aresenic was also frequently used for daggers (46%) and axes (45%). While Cypriot metalsmiths may have been aware of the advantages of using Tin Bronze for objects which required sharp and durable cutting edges, there may not have been much difference in the mechanical properties of Copper-Arsenic, Copper-Arsenic-Tin, Copper-Tin and other alloys in this respect. Copper-Arsenic, including high-Arsenic silvery alloys (over 4 wt% Arsenic), was also commonly used for daggers elsewhere. Eight daggers have recorded concentrations of Arersenic above 4 wt%, suggesting an occasional desire for a silver-grey surface. The maximum recorded concentration of Arsenic in both daggers (5.9 wt%) and axes (5.5 wt%) is again below the point at which brittleness would have occurred. Either metalsmiths were aware of this threshold or using ores with natural concentrations of Arsenic below this level.

In the case of pins, unalloyed Copper and Copper-Arsenic account for 64% of the assemblage. These objects did not require hardness, sharpness or tensile strength and did not need to withstand the punching of an eyelet. Practical considerations of metal availability might therefore be expected to be paramount in the selection of material for their manufacture. This would appear, however, to be only part of the story. Eleven pins have recorded Aresenic levels above 4 wt%, with 10 in the 4–6 wt.% range and one with a concentration of 15.6 wt%. This suggests the use of high-Arsenic Bronze to achieve an aesthetically-pleasing silvery surface. A similar finding of 5 and 10 wt% As in two Early Bronze Age pins from Psematismenos suggests that the inverse-segregation properties of Copper-Arsenic alloys, which lead to marked Arsenic enrichment at the surface, were exploited for the manufacture of pins throughout the prehistoric Bronze Age in Cyprus. Any resulting brittleness is likely to have been obviated by minimal post-cast working and the low stress use environment of these objects.

A comparison of median values shows a range of 0.25–2.5 wt% Arsenic for different artefact types. Thus the Arsenic content in most artefacts is within the range occurring in some Cypriot ores and the use of both unalloyed and Arsenical Copper is likely a result, for the most part, of the smelting of ores more or less naturally rich in Arsenic.

The highest median Arsenic content is found in axes and daggers and the lowest in toggle pins. It has been suggested that domestic items are likely to have gone through more recycling episodes than prestige items, with lower resulting concentrations of Arsenic. This might apply to the needles, awls, razors and tweezers in the assemblage, which have lower median values than axes and daggers, but different factors were at play when it comes to toggle pins. Toggle pins have the lowest median Arsenic and the highest median Tin values, suggesting the use of low-Arsenic, high-Tin Bronze for these items.

Copper with tin between 5 and 12 wt%, considered a typical Tin Bronze, has excellent casting qualities and hardens considerably when hammered, with the optimal Tin concentration that balances hardness against brittleness considered to be about 10%. Changes in colour which occur with increasing concentrations of Tin, from red to golden and ultimately (at 18 to 33 wt%) to silver—are also thought to have played an important role in prehistory.

In the analysed sample Tin alloys occur least often among spearheads (19%), pins (27%) and razors (37%), near or above 50% of the assemblage in the case of daggers (44%), needles (49%), axes (53%) and awls (59%), and well above 50% in the case of tweezers (65%) and toggle pins (76%). Median Tin content is also highest among tweezers and toggle pins; and the use of high-Tin Bronze (over 13 wt%) is greatest among toggle pins and plain pins.

These results suggest a variety of factors behind the use of Tin. Metalsmiths appear to have preferred Tin alloys for artefacts which required edge-hardness (daggers and axes), although in neither instance do Tin alloys dominate the assemblage. In the case of needles and perhaps awls, the relatively high incidence of Tin bronze may be due to the opportunistic use of small quantities of metal prepared for other purposes or from recycled metal. In the case of tweezers and toggle pins, where the mechanical benefits of Tin Bronze are also unlikely to have been functionally relevant and the average concentration of Tin is at or above the level at which changes in surface colour would have occurred, the use of Tin alloys is best explained as a deliberate attempt to achieve a golden or, at Tin concentrations above 18 wt%, a silvery surface colour. The latter is relevant also to a number of the plain pins. Although Tin is recorded at above 1 wt% in only 27% of the plain pin sample, when present at these levels the average Tin concentration is very high at 15.2 wt%.

The 9 plain pins with Tin recorded at over 13 wt% are all large examples, over 20 cm and up to 40 cm long. In 6 of these the Tin content, at 17.0–20.8 wt%, approximates or exceeds the point at which the surface is likely to have taken on a silver colour. Another 11 pins have recorded Arsenic levels at above 4 wt%. While these are generally smaller, there are 7 examples over 20 cm and up to 28.6 cm long. The correlation between length and high levels of Tin or Arsenic is not as strong among toggle pins, which are generally shorter (though often heavier) than plain pins; only 6 of 13 toggle pins over 20 cm long have recorded Tin levels above 13 wt%. All, however, are Tin Bronzes and the incidence of Tin above 10 wt% across the toggle pin sample is high (44.2%), with 9 in the 17.0–21.3 wt% Tin range. The use of high Arsenic and high Tin alloys to achieve a particular surface colour is thus greatest among pins of both types.

The replacement of Arsenical Bronze by Tin Bronze, with a possible transition period represented by the use of Copper-Arsenic-Tin and Copper-Tin-Arsenic alloys, is usually assigned to the Late Bronze Age in Europe and Western Asia. In Cyprus the use of standard binary Bronzes, typically with a Tin content between 8 and 10 wt%, is thought not to have been fully established until the Late Bronze Age, at which time Arsenic ceased to be used as a major alloying metal for Copper. This has been attributed to the introduction of new metallurgical techniques at the beginning of this period, but the Lapithos data raise the possibility that it was to some extent an evolutionary process which began during the course of the Middle Bronze Age. While the use of Tin, however, increased at Lapithos during the Middle Bronze Age, Arsenical Copper, which has valuable properties in itself and was easily obtained by Cypriot metalsmiths, continued to be used in significant quantities until the demise of the settlement at the end of the Middle Bronze Age.

Copper Zinc alloys, typically known as Brass, are widely believed not to have become common until the Roman era. Chemical analyses of Bronze Age Cypriot Copper alloys, conducted mostly in the 1940s, revealed the presence of significant amounts of Zinc (over 1%) in a number of artefacts but these results were subsequently discounted. In the analyses reported by Charalambous and Webb, however, Zinc was detected in 14 artefacts in a recorded range of 0.5–4.5 wt%. Observation of the analytical spectra of the 6 objects containing above 1 wt% Zinc confirms the presence higher amounts of Zinc in these artefacts.

Zinc is present in Cypriot Copper sulphide ores and low concentrations of Zinc in locally produced artefacts might be expected. Zinc concentrations above 1% are rare, however, in Late Bronze Age Copper alloys, and it has long been assumed that any Zinc present would have been removed by initial roasting or smelting. A similar loss of Zinc might be expected for pre-Late Bronze Age Copper alloys. Its presence at above 1 wt% in 6 artefacts therefore requires explanation. Two instances, a pin of Copper-Zinc with 4.2 wt% Zinc and a dagger of Copper-Tin-Zinc with 3.9 Zn, are almost certainly imports.

In the case of two spearheads, with 1.1 wt% and 1.8 wt% Zinc, surface readings have possibly exaggerated the amount of Zinc which may in fact fall within the upper limit expected of locally smelted ores. An engraved mushroom-headed toggle pin and a chisel, both Copper-Tin-Zinc alloys and of local types, have reported concentrations of 3.0 and 4.5 wt% Zinc respectively. They are currently the earliest identified Zinc alloys from Cyprus. This should prompt a review of several objects with high levels of Zinc from Late Bronze Age contexts on Cyprus, the date of which has been questioned on the grounds that brass was unknown on the island before the mid-first century BC. A similar revision of the early history of Copper-Zinc alloys in Anatolia and Iran is underway.

Lead (Pb) was detected in 90% of the X-Ray Fluorescence Spectrometry sample (379 objects), in concentrations from 0.1–7.5 wt% (with an outlier (a razor) recorded as 15.5 wt%) and at above 1 wt% in 17.6% of the assemblage. The addition of Lead to Copper-base alloys and Bronze lowers the melting point and improves the fluidity of the melt during casting but does not increase the working properties of the cast Bronze and may reduce the hardness and toughness of an alloy when added in larger quantities (8–25 wt%). The possible presence of Lead alloys in Cyprus in the Early Bronze Age and Middle Bronze Age has been discussed in several previous publications. Use of Leaded Copper alloys is also widely recognised from the end of the 3rd Millennium in the Levant, where the occasional presence of Lead in high concentrations, despite its detrimental effects, has led to the suggestion that it was added to economise on more expensive metals or/and reduce fuel consumption. Recent analyses have also shown the presence of Lead in concentrations generally below 1 wt% but up to 3.5 wt% in Late Bronze Age artefacts from Cyprus.

As Lead is not present in Cypriot Copper ores or occurs in concentrations well below 0.5 wt%, and the Tin ores exploited in the Bronze Age contain only a few parts per million of Lead, the occurrence of this metal, even at levels below 1 wt%, has been ascribed to a deliberate addition. Lead ores (galena), however, are very rare on Cyprus and not associated with Copper ores, and artefacts with a Lead content above 0.5 wt% may, alternatively, come from the recycling of imported Leaded Bronzes or from the use of non-Cypriot ores containing Lead minerals. There is in fact a considerable degree of correlation in the X-Ray Fluorescence Spectrometry sample between Tin and Lead. Lead occurs at over 1 wt% in 72 artefacts, 88.9% (64) of which also contain more than 1% wt% Tin. In the Lapithos sample, it is also possible that Lead was introduced through co-melting Copper or Bronze with imported Lead spiral rings, a significant number of which were recovered in the tombs.

It was once believed that Tin Bronze did not appear on Cyprus until the beginning of the Middle Bronze Age. It is now clear, however, that imported Tin Bronzes (and Tin metal) were reaching Cyprus and being produced locally almost half a millennium earlier. Compositional analyses have identified three artefacts from the first phase of the Early Bronze Age as Tin Bronzes. Two appear to be imports from Anatolia. The third, an axe with a Lead isotope ratio consistent with Copper from the Limassol Forest area, suggests that local metalsmiths were producing Bronzes using local Copper and imported Tin. Six Tin Bronze earrings of similar date from Sotira in the south of the island further suggest that this alloy was already being used in Cyprus to achieve a colour effect similar to that of Gold.

Tin is rare in analysed objects from the later Early Bronze Age, most of which are of relatively pure Copper or Arsenical Bronze. Tin Bronzes reappear in Cyprus in the early years of the Middle Bronze Age sometime after 2000 BC. Charalambous and Webb's analyses suggest that the amount of Tin entering Cyprus at this time may have been underestimated and perhaps significantly so. Previous studies have concluded that Tin Bronze did not become common until the end of the Middle Bronze Age, at which time about half the artefacts produced were made of Tin Bronze or Arsenical Tin Bronze. In the X-Ray Fluorescence Spectrometry analyses reported by Charalambous and Webb 68% of analysed Middle Bronze Age artefacts contain Tin: 21% with a recorded Tin content from traces to 0.9 wt%, 23% from 1 to 6 wt.%, 6% from 6.1 to 10 wt% and 18% over10 wt%.

Since Tin does not occur in Cyprus and is not present in Cypriot Copper ores, Tin-Bronze could only have been obtained via long-distance exchange or made locally using tin imported as a stanniferous mineral (mineral containing Tin) or in the form of Tin-Bronze ingots, scrap or finished artefacts, the latter melted and perhaps mixed with Cypriot Copper and reworked over time to produce second or third generation Bronzes in local styles. The recycling of Tin-Bronze (or the use of imported Copper containing low concentrations of Tin as an impurity in the ore) is indeed indicated by the occurrence of Tin at under 1 wt% in 19% of the analysed sample. Recycling practices and the prevalence of mixed alloys have rarely been acknowledged in discussions of pre-Late Bronze Age metallurgy in Cyprus. An increase in the intensity of recycling through the Middle Bronze Age is also suggested by the decrease over time in artefacts with over 1% Arsenic and an increase in those with concentrations below 1 wt%. This drop-off in Aresenic content may be a result of repeated melting and post-casting operations leading to the depletion of Arsenic by oxidation and evaporation.

An earlier study of the composition and Lead isotope signatures of over 130 Middle Bronze Age Copper-base artefacts from Cyprus, 75 of which are from Lapithos, concluded that of 80 artefacts analysed that seem to be made of Cypriot Copper only about 10% contain Tin, whereas 20 with Lead isotope ratios consistent with published data from the Iranian mines of Deh Hossein and Karkas all contain Tin (and 14 objects have over 20 wt% Tin). If objects made of Copper from Iran (or at least inconsistent with known ore sources on Cyprus) are consistently high-tin Bronzes, it seems logical to assume that the imported material was Bronze. Equally, the use of this alloy for typologically Cypriot objects, including daggers, awls and pins, suggests that it was reaching Cyprus in the form of Bronze ingots or scrap or as finished artefacts which were melted and reworked in Cyprus.

The mixing of Cypriot Copper with imported Tin Bronze should also be considered. A previous study identified 4 isotopic groups amongst artefacts from Lapithos, consistent with Copper ores from Cyprus, the Aegean, Iran and the Taurus Mountains. While the patterning in the Lead isotope data does not suggest mixing, the addition of Cypriot Copper, which has a very low lead content, to bronzes made of Copper from external sources may not significantly change the isotopic composition. Artefacts with lead isotope fingerprints of Iranian or Taurus Copper may, therefore, have been made by mixing imported Tin Bronze with Cypriot Copper to make local Bronzes. This is indeed suggested by the fact that objects with Lead isotope signatures inconsistent with Cypriot ores are of local types. The very varied Tin content and large group of artefacts with very low Tin in the Lapithos assemblage also support a hypothesis of mixing as well as of the recycling of imported metal, and it is likely that metalsmiths were engaging in both practices.

The analysed assemblage was recovered from tombs allocated to two overlapping phases of the Middle Bronze Age. While analytical problems associated with X-Ray Fluorescence Spectrometry surface readings may be exaggerating the presence of Tin and Lead to some extent, the two sets of data are internally consistent and allow a broad assessment of the compositional profiles of 9 artefact types and changes in metallurgical practices at Lapithos over the Middle Bronze Age.

The results suggest that the Middle Bronze Age was a period of significant metallurgical development in Cyprus, which saw the reintroduction and a steady increase in the use of Tin Bronze. They also suggest a more complex pattern of alloy use than previously thought to have been the case and a greater degree of re-cycling and probably mixing of Cypriot Copper with imported Bronzes, practices about which we have been largely ignorant until now.

Indeed, one of the most significant observations to arise from this study is that metalsmiths at Lapithos may only rarely, if at all, have been producing alloys by co-melting Copper with one or more secondary metals—but rather using naturally high-Arsenic Copper ores from the Limassol Forest region, recycling imported bronze artefacts and mixing local Copper with imported Bronzes. The latter likely also explains the presence in some artefacts of Lead and Zinc in concentrations which do not match the chemistry of Cypriot ores and must ultimately be derived from imported metal.

The metal industry at Lapithos also appears to have been more sophisticated than previously suspected. In some cases it seems that little attention was paid to the selection of an alloy, with unalloyed Copper, Copper-Arsenic with a range of Arsenic concentrations and Tin Bronze alloys used as available; for example, for smaller items like needles. In other cases specific alloys were matched with object types. This is most apparent in the case of spearheads, which are primarily of unalloyed Copper and Arsenical Copper, and toggle pins, 76% of which are Tin alloys. Charalambous and Webb's results suggest that metalsmiths were making conscious choices about appropriate alloys for different categories of object both in relation to their mechanical and aesthetic properties.

The repertoire of tools and weapons in Bronze Age Cyprus remained resistant to the typological developments which marked the Levant from the beginning of the Middle Bronze Age. This has long been seen as an indication of the isolation and conservatism of Cypriot metalsmiths. It may equally, however, suggest that these objects were considered ‘fit for purpose’ and that the majority were produced by ‘common craftspeople’ (as opposed to ‘master crafters’ or ‘virtuosi’); whose skills were fully embodied but whose products remained ‘traditional’. The pins, and in particular the toggle pins, arguably, however, belong to another category. While many are simple items, others were produced with special-purpose alloys and stand out in terms of their size, surface colour and decoration. They also show considerable diversity in form, size and composition; and both imports and pins emulating Anatolian and Syrian types as well as new indigenous forms are in evidence. This suggests that some smiths at Lapithos were willing to experiment and apply new techniques to satisfy a local demand for original objects of high social value.

That Lapithos played a key role in developments in metalworking during the Middle Bronze Age is clear. It is also likely to have been the principal port from which Cypriot Copper was exported and its rise to prominence is roughly contemporary with the establishment of Assyrian trading colonies at Kültepe and with evidence for the use of Cypriot Copper at Mari and Babylon, at Malia in Crete and possibly on Kos in the Middle Bronze Age. Several lines of evidence suggest that it was an active participant in a trade in raw metals conducted along sea routes which passed between the south coast of Anatolia and the north coast of Cyprus in the first half of the 2nd Millennium BC. The results reported by Charalambous and Webb indicate that Tin, probably in the form of Tin Bronze, was reaching Lapithos from foreign sources in some quantity.

The extent to which Lapithos may have been managing the distribution of imported Tin, Copper, Bronze and other metals (Lead, Silver and Gold) to metalsmiths and consumers across the island remains unclear. While there is good evidence for metalworking at Middle Bronze Age settlements in the centre and south, no other site has produced anywhere near the quantity of metal recovered in the cemeteries at Lapithos. In this context, the level of metalworking activity, expertise and access to both distant local ores and imported materials suggested by the analyses reported by Charalambous and Webb should come as no surprise.

See also...

Measurements were also taken on corroded and cleaner surface areas on the same artefact, in order to see how the level of corrosion had affected the composition, focusing on the secondary elements of Tin, Lead, Arsenic and Iron that were detected in the majority of the artefacts. Measurements on corrosion areas showed much lower values for Tin, Lead and Arsenic, when compared with those on original surfaces. Only Iron values were higher. If an object was free of visible corrosion, measurements were conducted across the surface in order to examine the homogeneity of the chemical composition.

Two objects in the X-Ray Fluorescence Spectrometry sample, a spearhead and axe, had also previously been subject to spectrographic analysis. The spearhead was identified in both the spectrographic and X-Ray Fluorescence Spectrometry analyses as Copper with an almost identical amount of Aresenic (0.7 and 0.6 wt% respectively). The axe was identified in both programs as a Copper-Aresenic-Tin alloy with similar readings of Aresenic (2.3 and 2.15 wt%) but a markedly higher spectrographic reading of Tin (about 9 wt%) compared to that achieved by X-Ray Fluorescence Spectrometry (3.5 wt%). This is perhaps to be explained by the likelihood that the drilled sample was taken before the object was cleaned and ‘may not have penetrated the corrosion very deeply’. The X-Ray Fluorescence Spectrometry result, achieved after removal of the surface encrustation, may be more accurate.

With regard to the identification of alloys, Charalambous and Webb used an elemental concentration of over 1.0 wt% for Aresenic and Tin. This reflects the level at which changes in mechanical properties are likely to have become evident to metalsmiths, but did not assume that these concentration limits define intentional alloys. In the case of Aresenic, in particular, the minimum presence required to distinguish the addition of this metal from the use of ores naturally rich in Arsenic is a matter of controversy and especially relevantb in the case of Cyprus, where polymetallic ores with a reported Arsenic content of 0.5–7.6 wt% are available in the Limassol Forest region. Previous works have suggested the presence of 1–2 wt.% Arsenic as indicative of an intentional alloy, however, other works propose 2.5 wt% as the minimum for deliberate Cypriot alloys. Charalambous and Webb's results do not suggest an obvious threshold, but a continuum in line with natural ore content and should probably be viewed as signalling the use of arsenic-rich ores rather than the addition of Aresenic for most Arsenical Copper objects.

Tin is rare in copper ore deposits generally and when present at more than 1.0% is usually assumed to have been added intentionally. Cypriot ores contain no Tin. This suggests that a 1 wt% threshold for the identification of Copper-Tin alloys is appropriate, whether as a result of recycling or mixing (using Cypriot Copper and imported Bronzes) or an intentional addition for the improvement of the metal.

The compositional analysis by X-Ray Fluorescence Spectrometry revealed significant variability, in terms of both alloying elements and alloy types, among the 415 Copper artefacts. Arsenical Bronze (Copper-Aresenic) is the most common (152 artefacts, 37%), while Arsenic-Tin Bronzes (Copper-Aresenic-Tin) occur at the second highest frequency (117 artefacts, 28%). Tin was recorded at over 1 wt% in 49% of the sample and Lead in 18%, while Zinc occurred at over 1 wt% in 6 artefacts. This higher than expected incidence of Copper-STin alloys and of Lead may be driven in part by our alloy threshold of 1 wt%, together with the likely enrichment of Tin and Lead at and beneath the original surface.

Tin occurs in detectable amounts in 283 artefacts (68% of the total), in concentrations ranging from 0.1 to 21.3 wt%. Notably, artefacts from the early/middle Middle Bronze Age have lower Tin concentrations overall than those in the middle/late Middle Bronze Age group, but there are high Tin Bronzes in the earlier period. The middle/late sample also shows a more even presence of Tin across the concentration range from 6 to 18 wt%.

Lead was detected in 90% of the assemblage (379 artefacts), in concentrations from 0.1 to 7.5 wt%. A single outlier is a razor with a Lead concentration of 15.5 wt%. The vast majority of artefacts (350) have a Lead concentration lower than 2 wt% (only 29 artefacts exceed 2 wt%). Iron was detected in all artefacts, in concentrations from 0.2 to 2.1 wt%, but the great majority have an iron content below 1 wt%. Sulphur was detected in 66% of the assemblage (278 artefacts), in concentrations from 0.3 to 2 wt% but, as with Iron, most artefacts have Sulphur concentrations below 1 wt%. Zinc was detected in 14 artefacts (0.5–4.5 wt%) and Antimony (Sb) in 14 artefacts (0.1–0.3 wt%).

Tin was not detected in 132 objects (32% of the total). One hundred and eighty-two contain traces to 6 wt.% Tin. Since Cypriot Copper ores do not contain Tin, the Tin concentration of the less than 6 wt% group is not due to impurities in the ore, and is best explained as a result of the melting down of scrap metal or Bronze artefacts mixed with Arsenical Copper. This is supported by the fact that the majority of low-Tin artefacts contain significant concentrations of Arsenic (over 1 wt%).

On the other hand, 101 objects have recorded concentrations of 6–21.3 wt% Tin. In this case, the great majority of artefacts contain much lower concentrations of Arsenic (Arsenic exceeds 1 wt% in only 17 artefacts), especially in the high-Tin group (over 13 wt%, 52 artefacts) where the Arsenic content is in almost all cases below 1 wt% (Arsenic exceeds 1 wt% in only 6 objects).

In comparing the results from the two phases, there is a decrease in the number of objects with no Tin, from 56% to 25% of the sample, with a corresponding increase in all other concentration groups. Notably, the increase in the traces to 6 wt.% group, from 30% to 48%, suggests a significant rise in the quantity of recycle metal, and specifically Tin Bronze, in circulation at Lapithos in the middle/late Middle Bronze Age; while the higher incidence of objects in the over 6 wt% groups (from 14% to 27%) indicates an increase also in the use of medium-to high-Tin Bronze.

A slight decrease overall in the presence of arsenic from the early/ middle to middle/late Middle Bronze Age has already been noted. A more nuanced decrease in the latter period of artefacts in the over 1 wt% Arsenic groups and a corresponding increase in the percentage in the low-Arsenic group (traces to 0.9 wt%). This drop-off in Aresenic content concomitant with an increase in the use of Tin may be due to a decrease over time in the use of high-Arsenic ores or increased recycling practices, as already suggested by the rise in the traces to 6 wt.% Tin group, with repeated melting and post-casting operations leading to a depletion of Arsenic by oxidation and evaporation of Arsenic Trioxide (As₂O₃) fumes.

The 41 spearheads are primarily of Copper-Arsenic, with a small number of unalloyed copper and Copper-Arsenic-Tin and one of Copper-Tin. Copper and Copper-Aresenic are also predominant among the 25 spearheads analysed by Proton-induced X-ray Emission Analysis and Neutron Activation Analysis. Tin is, however, present in the Proton-induced X-ray Emission Analysis and Neutron Activation Analysis samples at sub-alloy levels (less than 0.01–0.53 wt% and less than 0.01–0.93 wt% respectively), and in the X-Ray Fluorescence Spectrometry data from below detection levels to 19.3 wt%; with a median nondetectable value. Only two spearheads have a significant amount of Tin. The Aresenic readings in the X-Ray Fluorescence Spectrometry data are comparable, on median, with the Proton-induced X-ray Emission Analysis and Neutron Activation Analysis data and within the range of naturally occurring high Arsenic ores in most cases. Only seven spearheads with more than 4 wt% Aresenic might be considered deliberate Copper-Aresenic alloys. The low incidence of Tin Bronze is not surprising. If the effectiveness of a spearhead depended more on its momentum at impact than edge-sharpness, there may have been little mechanical benefit to be gained in using valuable Tin. Most previously analysed Cypriot spearheads are also of unalloyed Copper or Arsenical Copper.

The 85 daggers are primarily of Copper-Arsenic and Copper-Aresenic-Tin, with smaller numbers of Copper-Tin and unalloyed Copper. The incidence of Tin, particularly in the ternary alloy Copper-Aresenic-Tin, is significantly higher in the X-Ray Fluorescence Spectrometry sample than among 21 daggers analysed by Proton-induced X-ray Emission Analysis and Neutron Activation Analysis, with a consequent reduction in the incidence of Copper and Copper-Aresenic. Across all data sets, however, daggers show more compositional diversity than spearheads and a greater use of Tin. This suggests that Cypriot metalsmiths were aware of the advantages of using Tin Bronze, which can be hammered to produce a hard edge, for objects which required sharp and durable cutting edges.

The 31 axes are of Copper-Aresenic-Tin and Copper-Aresenic with one of unalloyed Copper. Tin is present below 1 wt% in 12 axes, with only 2 recording no Tin. The number with tin at over 1 wt% is high, at 53% of the sample, with a median of 1.3 wt%. Arsenic is present in all samples, with a median of 2.5 wt%. The Proton-induced X-ray Emission Analysis and Neutron Activation Analysis samples recorded a lower incidence of Tin alloys and a significantly lower median Tin content. While in both cases this may reflect the problem of surface Tin enrichment, the recorded presence of Tin at or over 1 wt% in over half the sample and at trace level in another 16 axes, together with lead at over 1 wt% in 5 examples, suggests that most are made of recycled Bronze or local Copper mixed with imported metal containing some Tin. It would seem that few, if any, of the Lapithos axes were made of Copper cast directly from Cypriot ores.

The 37 needles are of unalloyed copper and Copper-Aresenic-Tin, with lower numbers of Copper-Arsenic and Copper-Tin. The high incidence of unalloyed Copper for these simple items is not surprising. Traces of Tin (under 1 wt%) in only 5 of the 14 needles of unalloyed Copper and 2 of the 5 Copper-Arsenic needles also indicate more frequent use of first generation metal. Given, however, that there seems no reason to use Tin at all for such artefacts, the presence of more than 1 wt% Tin in 49% of the sample suggests that they were often made opportunistically from small quantities of metal prepared for other purposes or from recycled metal.

Half of the 16 awls are of Copper-Aresenic-Tin and the remainder of unalloyed Copper and Copper-Arsenic with one of Copper-Tin. While the sample is small, the prevalence of Tin, recorded at over 1 wt% in 56% of awls, is clear. The concentration of Tin ranges from less than 0.1 wt% to as high as 17.2 wt%, with a median of 1.65 wt%. Arsenic ranges from under 0.1–4.4 wt%, with a median of 1.35 wt%. Thus few awls appear to be deliberate Copper-Aresemnic alloys, while over half are Copper-Tin alloys. Another 2 have traces of Tin and appear, therefore, to be of recycled metal.

Ten of the 19 razors are Copper-Arsenic, with 5 of Copper-Tin, 3 of Copper-Arsenic-Tin and 1 of unalloyed Copper. The incidence of tin at recorded levels above 1 wt% in 42% of the sample is only slightly lower than that of daggers (44%). Surface readings on thin objects corroded from both sides can, however, appear richer in Tin than thicker objects of the same original composition which still have a less Tin-rich core preserved. Arsenic is present in the razor sample from below 0.1-4.3 wt%, with a median of 1.6 wt%. Nine razors analysed by Proton-induced X-ray Emission Analysis and Neutron Activation Analysis are also primarily of Copper-Aresenic, with 2 of unalloyed Copper and 1 of Copper-Aresnic-Tin. Earlier compositional data for razors show a similarly high incidence of unalloyed and Arsenical Copper (13 of 15 analysed razors).

Seventy percent (70%) of the 34 analysed tweezers are of Copper-Aresenic and Copper-Aresnic-Tin. Tin was recorded at over 1 wt% in 65% of these objects, with a median of 5.55 wt%, and 9 (26.5% of all tweezers and 40.9% of those with Tin) were recorded with tin levels above 10 wt% and up to 20.0 wt%. The median overall Tin content is 2.45 wt%. These high Tin readings may to some extent be due to problems noted above with respect to surface readings on razors. Tweezer blades are typically even thinner than razors. The incidence of Tin at above 1 wt% in the Neutron Activation Analysis data, however, is similar to that in the X-Ray Fluorescence Spectrometry sample, and 2 of the Copper-Tin examples also had high levels of Tin, at 11.4 wt% and 14.29 wt%.

The 48 plain pins (i.e. pins without eyelets) are compositionally diverse. The presence of Tin at over 1 wt% in only 26% of the sample is lower, and for the most part significantly lower, than in all other artefact groups except spearheads. The recorded Sn content ranges from under 0.1 wt% to 20.8 wt% with a median non-detected value. When present above 1 wt%, however, Tin concentrations have a median of 17 wt%. Plain pins are thus less likely than other artefact types (with the exception of spearheads) to contain Tin, but when they do they are all high-Tin bronzes. Arsenic levels range from under 0.1 wt% to 15.6 wt%, with a median of 1.4 wt%. The Copper-Zinc pin contains 4.2 wt% Zinc and is technically brass. It is of non-local form and almost certainly an import. Nine pins analysed by Neutron Activation Analysis show the same preference for Copper and Copper-Aresenic as the X-Ray Fluorescence Spectrometry sample. Arsenic levels range from 0.005 to 7.18 wt%, with a median of 2.34 wt%, higher than that of the X-Ray Fluorescence Spectrometry group.

The 77 toggle pins are also of varied composition, with only 4% of unalloyed Copper. Tin was recorded at over 1 wt% in 76% of the sample and Lead at over 1 wt% in 43%, in both cases at a much higher level than in other artefact categories. Toggle pins have the highest median incidence of Tin and the lowest median incidence of Arsenic in the assemblage, as well as a significant component of Lead, recorded from traces to as high as 7.5 wt%, with a median of 0.85 wt%. One toggle pin contains Zinc at 3.0 wt% and one of Copper-Aresenic showed traces of Silver (0.7 wt%). Ten toggle pins analysed by Proton-induced X-ray Emission Analysis and Neutron Activation Analysis are of Copper-Tin, with a single example of Copper-Arsenic. The median concentration of Tin, at 11.36 wt%, is higher than in the X-Ray Fluorescence Spectrometry sample. Arsenic levels were again lower than in other artefact categories, with a median of only 0.15 wt%.

Some of the high-Tin Bronze pins may be imports or local imitations of Levantine pins. Twenty-one examples with a domed head, 81% of which are of Copper-Tin with a median Tin content of 15.15 wt%, are of a type known in Syria and Lebanon from about 2000 BC onwards. Toggle pins with mushroom-shaped heads, on the other hand, are local products and also predominantly Copper-Tin (67.7% of 31 examples), with a lower but still significant median Tin content of 9.5 wt%.

Arsenical Copper has several technical advantages which are likely to have led either to the selection of Arsenic-rich, polymetallic ores from the Limassol Forest region of Cyprus, or the addition of imported Arsenic-rich minerals, such as realgar/orpiment, or possibly the artificial Iron-Arsenic alloy, Speiss, to copper obtained from other ore bodies on the island. While there is no direct evidence for exploitation of the Limassol Forest ore bodies during the prehistoric Bronze Age, or indeed of any ore body on the island with the exception of that at Ambelikou, Lead isotope data suggest the use of ore from Laxia tou Mavrou and Petromoutti in the Limassol area already in the Early Bronze Age. The consistent use of Copper-Arsenic during the Middle Bronze Age at Lapithos leaves no doubt that imported Arsenic Sulphide or, more likely, high-Arsenic Copper ores from the other side of the island were available in significant quantities.

Mechanical properties change significantly with Aresenic concentrations as low as 0.5 wt%. Copper with increased Arsenic content in solid solution can be more hardened by cold work and high-Arsenic alloys are frequently favoured for cutting, carving and sewing tools. The presence of Arsenic also lowers the melting point of Copper, acts as a deoxidant and improves castability, although alloys containing more than ca. 7–8 wt.% Arsenic rapidly become too brittle to work cold. The formation of an Arsenic-rich phase (Cu₃As) also gives a silvery colour to Arsenical Copper alloys with more than 4 wt% Arsenic.

The preference for Copper-Arsenic among analysed spearheads, at 59% of the assemblage, suggests that the advantages of Copper with over 1 wt% Arsenic for casting large objects which were required to be strong and durable and which would not significantly benefit from the addition of Tin were understood by metalsmiths. The maximum recorded concentration of Aresenic, at 6.5 wt%, further suggests an awareness of the brittleness associated with alloys containing more than 7–8 wt.% Arsenic, while the occurrence of Aresenuc at over 4 wt% in 6 spearheads may indicate an intention in some instances to achieve a silvery surface colour.

The other artefact class in which Copper-Aresenic predominates, at 50% of the assemblage, is razors. It may be that metalsmiths understood that the greater ductility and toughness of Copper-Arsenic over unalloyed copper and Copper-Tin alloys made it better suited to the production of thinly hammered objects. The maximum recorded level of Arsenic, at 4.3 wt%, is again well below the brittleness threshold.

Copper-Aresenic was also frequently used for daggers (46%) and axes (45%). While Cypriot metalsmiths may have been aware of the advantages of using Tin Bronze for objects which required sharp and durable cutting edges, there may not have been much difference in the mechanical properties of Copper-Arsenic, Copper-Arsenic-Tin, Copper-Tin and other alloys in this respect. Copper-Arsenic, including high-Arsenic silvery alloys (over 4 wt% Arsenic), was also commonly used for daggers elsewhere. Eight daggers have recorded concentrations of Arersenic above 4 wt%, suggesting an occasional desire for a silver-grey surface. The maximum recorded concentration of Arsenic in both daggers (5.9 wt%) and axes (5.5 wt%) is again below the point at which brittleness would have occurred. Either metalsmiths were aware of this threshold or using ores with natural concentrations of Arsenic below this level.

In the case of pins, unalloyed Copper and Copper-Arsenic account for 64% of the assemblage. These objects did not require hardness, sharpness or tensile strength and did not need to withstand the punching of an eyelet. Practical considerations of metal availability might therefore be expected to be paramount in the selection of material for their manufacture. This would appear, however, to be only part of the story. Eleven pins have recorded Aresenic levels above 4 wt%, with 10 in the 4–6 wt.% range and one with a concentration of 15.6 wt%. This suggests the use of high-Arsenic Bronze to achieve an aesthetically-pleasing silvery surface. A similar finding of 5 and 10 wt% As in two Early Bronze Age pins from Psematismenos suggests that the inverse-segregation properties of Copper-Arsenic alloys, which lead to marked Arsenic enrichment at the surface, were exploited for the manufacture of pins throughout the prehistoric Bronze Age in Cyprus. Any resulting brittleness is likely to have been obviated by minimal post-cast working and the low stress use environment of these objects.

A comparison of median values shows a range of 0.25–2.5 wt% Arsenic for different artefact types. Thus the Arsenic content in most artefacts is within the range occurring in some Cypriot ores and the use of both unalloyed and Arsenical Copper is likely a result, for the most part, of the smelting of ores more or less naturally rich in Arsenic.

The highest median Arsenic content is found in axes and daggers and the lowest in toggle pins. It has been suggested that domestic items are likely to have gone through more recycling episodes than prestige items, with lower resulting concentrations of Arsenic. This might apply to the needles, awls, razors and tweezers in the assemblage, which have lower median values than axes and daggers, but different factors were at play when it comes to toggle pins. Toggle pins have the lowest median Arsenic and the highest median Tin values, suggesting the use of low-Arsenic, high-Tin Bronze for these items.

Copper with tin between 5 and 12 wt%, considered a typical Tin Bronze, has excellent casting qualities and hardens considerably when hammered, with the optimal Tin concentration that balances hardness against brittleness considered to be about 10%. Changes in colour which occur with increasing concentrations of Tin, from red to golden and ultimately (at 18 to 33 wt%) to silver—are also thought to have played an important role in prehistory.

In the analysed sample Tin alloys occur least often among spearheads (19%), pins (27%) and razors (37%), near or above 50% of the assemblage in the case of daggers (44%), needles (49%), axes (53%) and awls (59%), and well above 50% in the case of tweezers (65%) and toggle pins (76%). Median Tin content is also highest among tweezers and toggle pins; and the use of high-Tin Bronze (over 13 wt%) is greatest among toggle pins and plain pins.

These results suggest a variety of factors behind the use of Tin. Metalsmiths appear to have preferred Tin alloys for artefacts which required edge-hardness (daggers and axes), although in neither instance do Tin alloys dominate the assemblage. In the case of needles and perhaps awls, the relatively high incidence of Tin bronze may be due to the opportunistic use of small quantities of metal prepared for other purposes or from recycled metal. In the case of tweezers and toggle pins, where the mechanical benefits of Tin Bronze are also unlikely to have been functionally relevant and the average concentration of Tin is at or above the level at which changes in surface colour would have occurred, the use of Tin alloys is best explained as a deliberate attempt to achieve a golden or, at Tin concentrations above 18 wt%, a silvery surface colour. The latter is relevant also to a number of the plain pins. Although Tin is recorded at above 1 wt% in only 27% of the plain pin sample, when present at these levels the average Tin concentration is very high at 15.2 wt%.

The 9 plain pins with Tin recorded at over 13 wt% are all large examples, over 20 cm and up to 40 cm long. In 6 of these the Tin content, at 17.0–20.8 wt%, approximates or exceeds the point at which the surface is likely to have taken on a silver colour. Another 11 pins have recorded Arsenic levels at above 4 wt%. While these are generally smaller, there are 7 examples over 20 cm and up to 28.6 cm long. The correlation between length and high levels of Tin or Arsenic is not as strong among toggle pins, which are generally shorter (though often heavier) than plain pins; only 6 of 13 toggle pins over 20 cm long have recorded Tin levels above 13 wt%. All, however, are Tin Bronzes and the incidence of Tin above 10 wt% across the toggle pin sample is high (44.2%), with 9 in the 17.0–21.3 wt% Tin range. The use of high Arsenic and high Tin alloys to achieve a particular surface colour is thus greatest among pins of both types.

The replacement of Arsenical Bronze by Tin Bronze, with a possible transition period represented by the use of Copper-Arsenic-Tin and Copper-Tin-Arsenic alloys, is usually assigned to the Late Bronze Age in Europe and Western Asia. In Cyprus the use of standard binary Bronzes, typically with a Tin content between 8 and 10 wt%, is thought not to have been fully established until the Late Bronze Age, at which time Arsenic ceased to be used as a major alloying metal for Copper. This has been attributed to the introduction of new metallurgical techniques at the beginning of this period, but the Lapithos data raise the possibility that it was to some extent an evolutionary process which began during the course of the Middle Bronze Age. While the use of Tin, however, increased at Lapithos during the Middle Bronze Age, Arsenical Copper, which has valuable properties in itself and was easily obtained by Cypriot metalsmiths, continued to be used in significant quantities until the demise of the settlement at the end of the Middle Bronze Age.

Copper Zinc alloys, typically known as Brass, are widely believed not to have become common until the Roman era. Chemical analyses of Bronze Age Cypriot Copper alloys, conducted mostly in the 1940s, revealed the presence of significant amounts of Zinc (over 1%) in a number of artefacts but these results were subsequently discounted. In the analyses reported by Charalambous and Webb, however, Zinc was detected in 14 artefacts in a recorded range of 0.5–4.5 wt%. Observation of the analytical spectra of the 6 objects containing above 1 wt% Zinc confirms the presence higher amounts of Zinc in these artefacts.

Zinc is present in Cypriot Copper sulphide ores and low concentrations of Zinc in locally produced artefacts might be expected. Zinc concentrations above 1% are rare, however, in Late Bronze Age Copper alloys, and it has long been assumed that any Zinc present would have been removed by initial roasting or smelting. A similar loss of Zinc might be expected for pre-Late Bronze Age Copper alloys. Its presence at above 1 wt% in 6 artefacts therefore requires explanation. Two instances, a pin of Copper-Zinc with 4.2 wt% Zinc and a dagger of Copper-Tin-Zinc with 3.9 Zn, are almost certainly imports.

In the case of two spearheads, with 1.1 wt% and 1.8 wt% Zinc, surface readings have possibly exaggerated the amount of Zinc which may in fact fall within the upper limit expected of locally smelted ores. An engraved mushroom-headed toggle pin and a chisel, both Copper-Tin-Zinc alloys and of local types, have reported concentrations of 3.0 and 4.5 wt% Zinc respectively. They are currently the earliest identified Zinc alloys from Cyprus. This should prompt a review of several objects with high levels of Zinc from Late Bronze Age contexts on Cyprus, the date of which has been questioned on the grounds that brass was unknown on the island before the mid-first century BC. A similar revision of the early history of Copper-Zinc alloys in Anatolia and Iran is underway.

Lead (Pb) was detected in 90% of the X-Ray Fluorescence Spectrometry sample (379 objects), in concentrations from 0.1–7.5 wt% (with an outlier (a razor) recorded as 15.5 wt%) and at above 1 wt% in 17.6% of the assemblage. The addition of Lead to Copper-base alloys and Bronze lowers the melting point and improves the fluidity of the melt during casting but does not increase the working properties of the cast Bronze and may reduce the hardness and toughness of an alloy when added in larger quantities (8–25 wt%). The possible presence of Lead alloys in Cyprus in the Early Bronze Age and Middle Bronze Age has been discussed in several previous publications. Use of Leaded Copper alloys is also widely recognised from the end of the 3rd Millennium in the Levant, where the occasional presence of Lead in high concentrations, despite its detrimental effects, has led to the suggestion that it was added to economise on more expensive metals or/and reduce fuel consumption. Recent analyses have also shown the presence of Lead in concentrations generally below 1 wt% but up to 3.5 wt% in Late Bronze Age artefacts from Cyprus.

As Lead is not present in Cypriot Copper ores or occurs in concentrations well below 0.5 wt%, and the Tin ores exploited in the Bronze Age contain only a few parts per million of Lead, the occurrence of this metal, even at levels below 1 wt%, has been ascribed to a deliberate addition. Lead ores (galena), however, are very rare on Cyprus and not associated with Copper ores, and artefacts with a Lead content above 0.5 wt% may, alternatively, come from the recycling of imported Leaded Bronzes or from the use of non-Cypriot ores containing Lead minerals. There is in fact a considerable degree of correlation in the X-Ray Fluorescence Spectrometry sample between Tin and Lead. Lead occurs at over 1 wt% in 72 artefacts, 88.9% (64) of which also contain more than 1% wt% Tin. In the Lapithos sample, it is also possible that Lead was introduced through co-melting Copper or Bronze with imported Lead spiral rings, a significant number of which were recovered in the tombs.

It was once believed that Tin Bronze did not appear on Cyprus until the beginning of the Middle Bronze Age. It is now clear, however, that imported Tin Bronzes (and Tin metal) were reaching Cyprus and being produced locally almost half a millennium earlier. Compositional analyses have identified three artefacts from the first phase of the Early Bronze Age as Tin Bronzes. Two appear to be imports from Anatolia. The third, an axe with a Lead isotope ratio consistent with Copper from the Limassol Forest area, suggests that local metalsmiths were producing Bronzes using local Copper and imported Tin. Six Tin Bronze earrings of similar date from Sotira in the south of the island further suggest that this alloy was already being used in Cyprus to achieve a colour effect similar to that of Gold.

Tin is rare in analysed objects from the later Early Bronze Age, most of which are of relatively pure Copper or Arsenical Bronze. Tin Bronzes reappear in Cyprus in the early years of the Middle Bronze Age sometime after 2000 BC. Charalambous and Webb's analyses suggest that the amount of Tin entering Cyprus at this time may have been underestimated and perhaps significantly so. Previous studies have concluded that Tin Bronze did not become common until the end of the Middle Bronze Age, at which time about half the artefacts produced were made of Tin Bronze or Arsenical Tin Bronze. In the X-Ray Fluorescence Spectrometry analyses reported by Charalambous and Webb 68% of analysed Middle Bronze Age artefacts contain Tin: 21% with a recorded Tin content from traces to 0.9 wt%, 23% from 1 to 6 wt.%, 6% from 6.1 to 10 wt% and 18% over10 wt%.

Since Tin does not occur in Cyprus and is not present in Cypriot Copper ores, Tin-Bronze could only have been obtained via long-distance exchange or made locally using tin imported as a stanniferous mineral (mineral containing Tin) or in the form of Tin-Bronze ingots, scrap or finished artefacts, the latter melted and perhaps mixed with Cypriot Copper and reworked over time to produce second or third generation Bronzes in local styles. The recycling of Tin-Bronze (or the use of imported Copper containing low concentrations of Tin as an impurity in the ore) is indeed indicated by the occurrence of Tin at under 1 wt% in 19% of the analysed sample. Recycling practices and the prevalence of mixed alloys have rarely been acknowledged in discussions of pre-Late Bronze Age metallurgy in Cyprus. An increase in the intensity of recycling through the Middle Bronze Age is also suggested by the decrease over time in artefacts with over 1% Arsenic and an increase in those with concentrations below 1 wt%. This drop-off in Aresenic content may be a result of repeated melting and post-casting operations leading to the depletion of Arsenic by oxidation and evaporation.